Feasibility

With full process simulations and many years of experience, we support the part designers to choose the best solutionand saving cost production.

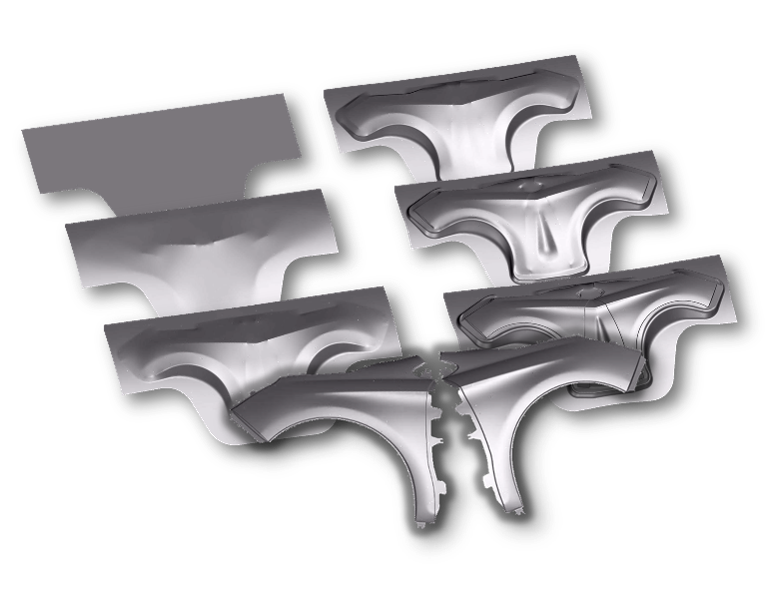

Process

We Develop the 3d Method plan, we model the dies surfaces and simulate each step in search of the best solution for the quality of parts, to lower production time waste.

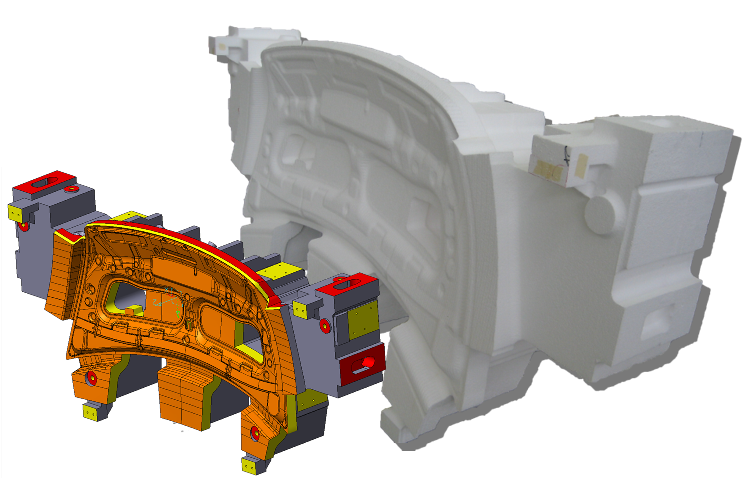

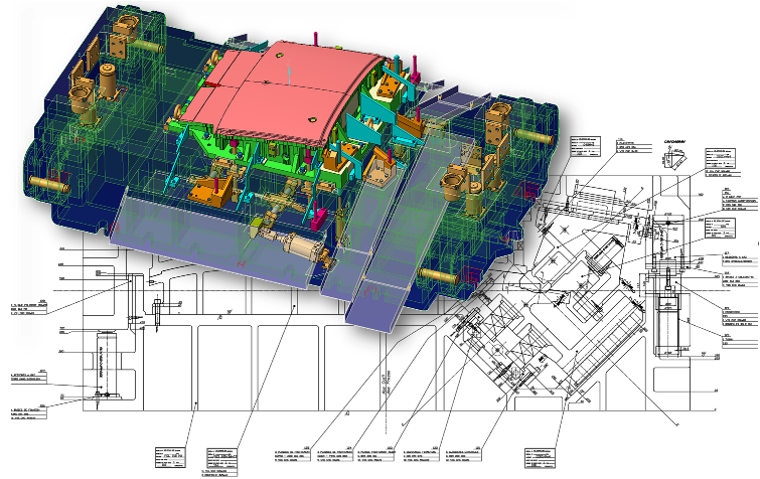

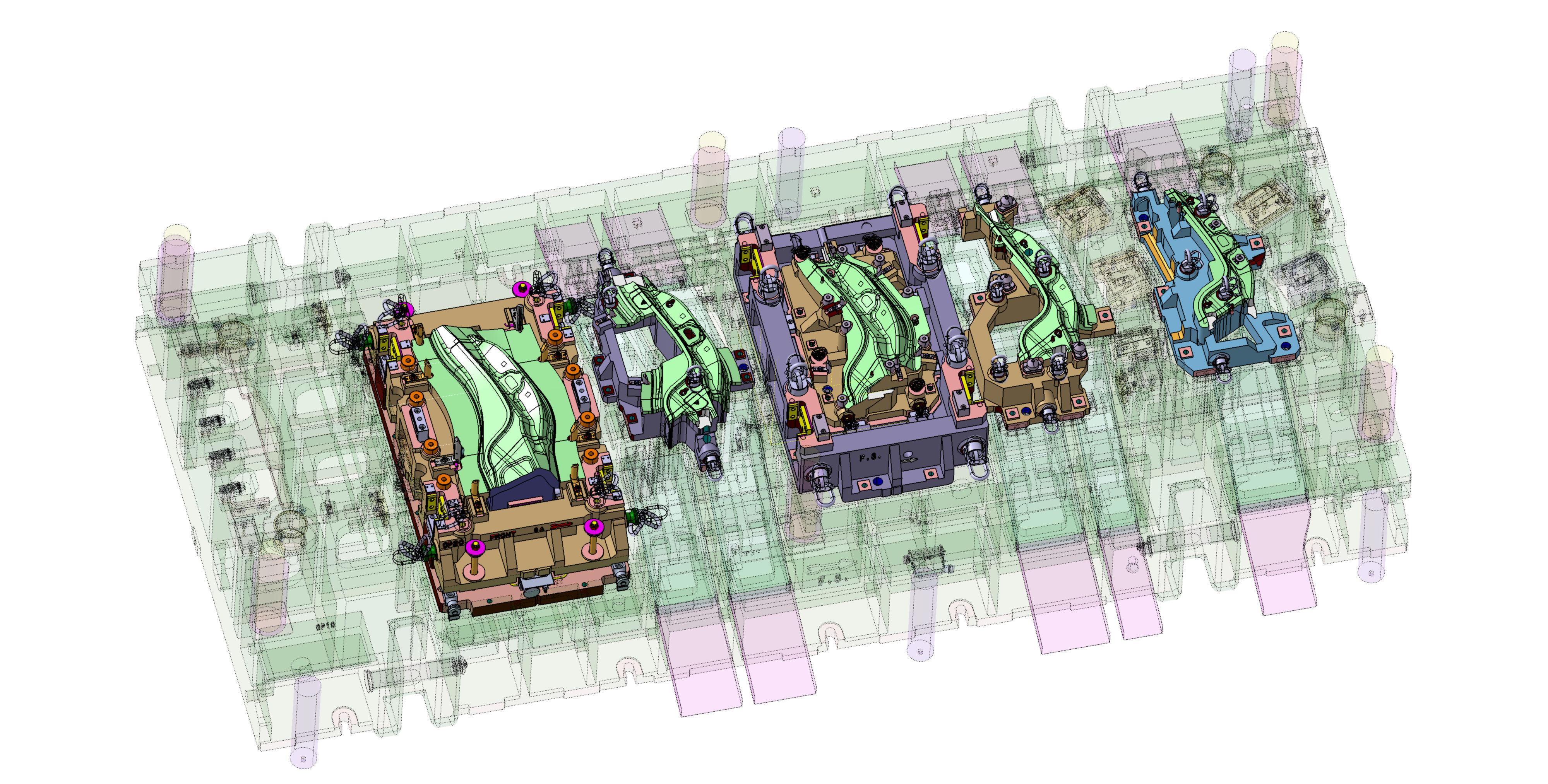

Dies-Design

Our higlhy skilled team, design any type of sheet metal die. Using volumetric CAD systems, following the customer's construction specifications, we design all sizes of dies, for prototype or high automatized productions.

Dies-Verify

The control and verification of the molding method and molds is followed simultaneously with the development. Over time, we have studied an efficient method and mold verification system, and developed verification strategies with partner companies made up of specific check-lists and specific software to simulate mold operation and automatic geometric control.

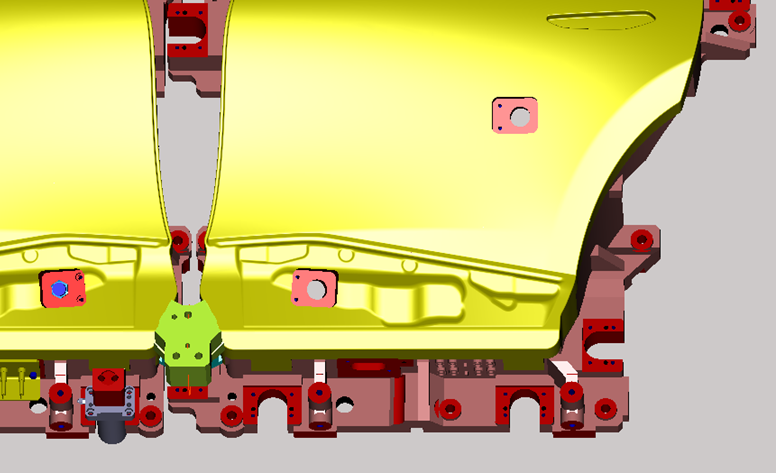

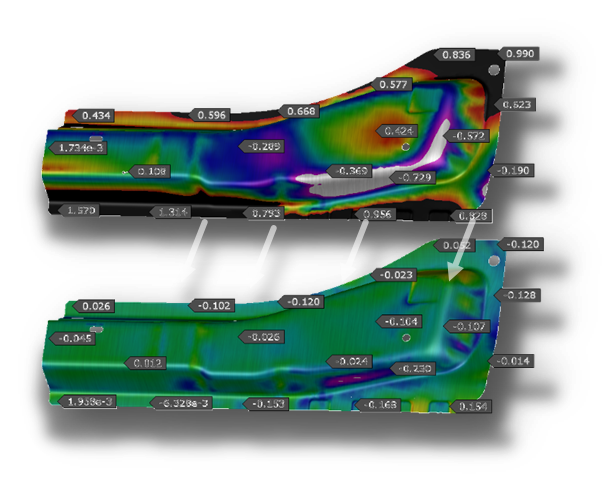

Springback

Our goal is: PART OK at first dies test. Thanks to a long experience and our customer feedback. We perform Virtual try-out. We use simulations software to check the sheet springback after each operation and make the best improvements to the dies.

Ledd

Industrialization for the production of sheet metal parts produced on a second plant. The method-project-springback-verification activity integrates all the specifications and potential of the supplier with the normal regulations of the car manufacturers, optimizing its production capabilities to the maximum with respect to the part to be produced and the cost-effectiveness of the project. We also perform rapid engineering services for prototyping.

Tryout

We have experienced staff able to follow the mold settings in the production sites of our customers.

Formation

We carry out on-the-job training for continuous improvement and to develop empathy with the project. With on-the-job training, training is carried out in coaching, by inserting one or more experts with specific skills into a work group and crucial for the project. Working side by side with the staff involved, even on rotation, the experts transmit new knowledge to the group, thus making training focused on the customer's needs.

Sustainability: towards zero

Sensitive to energy saving, we produce the electricity we consume. In collaboration with Dimensione Engineering we have created a photovoltaic system at our headquarters for the production of the electricity we use for our computers and for air conditioning.